38 Elasticity

Elasticity

| Review: | Chapter 47, Vol. I, Sound; the Wave Equation |

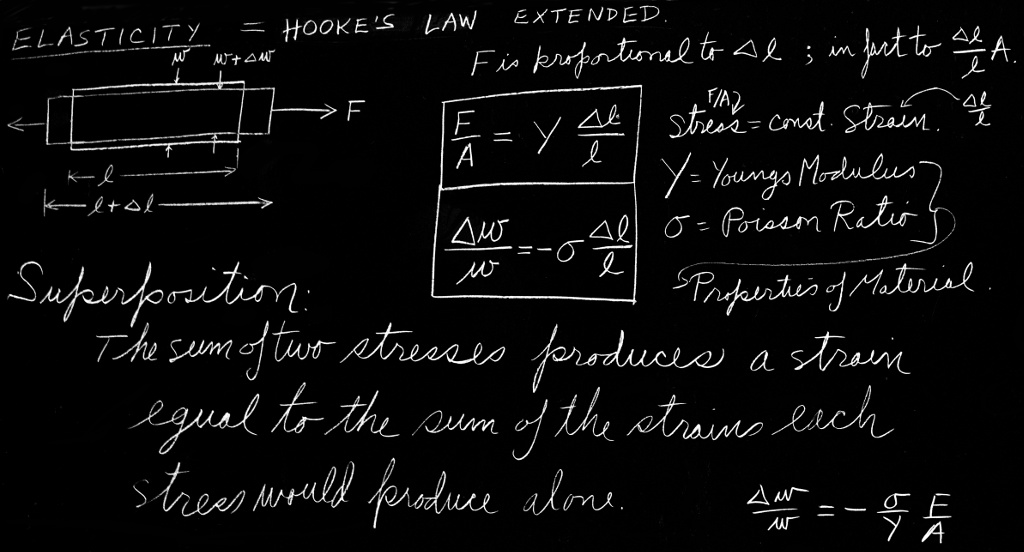

38–1Hooke’s law

The subject of elasticity deals with the behavior of those substances which have the property of recovering their size and shape when the forces producing deformations are removed. We find this elastic property to some extent in all solid bodies. If we had the time to deal with the subject at length, we would want to look into many things: the behavior of materials, the general laws of elasticity, the general theory of elasticity, the atomic machinery that determine the elastic properties, and finally the limitations of elastic laws when the forces become so great that plastic flow and fracture occur. It would take more time than we have to cover all these subjects in detail, so we will have to leave out some things. For example, we will not discuss plasticity or the limitations of the elastic laws. (We touched on these subjects briefly when we were talking about dislocations in metals.) Also, we will not be able to discuss the internal mechanisms of elasticity—so our treatment will not have the completeness we have tried to achieve in the earlier chapters. Our aim is mainly to give you an acquaintance with some of the ways of dealing with such practical problems as the bending of beams.

When you push on a piece of material, it “gives”—the material is deformed. If the force is small enough, the relative displacements of the various points in the material are proportional to the force—we say the behavior is elastic. We will discuss only the elastic behavior. First, we will write down the fundamental laws of elasticity, and then we will apply them to a number of different situations.

Suppose we take a rectangular block of material of length $l$, width $w$, and height $h$, as shown in Fig. 38–1. If we pull on the ends with a force $F$, then the length increases by an amount $\Delta l$. We will suppose in all cases that the change in length is a small fraction of the original length. As a matter of fact, for materials like wood and steel, the material will break if the change in length is more than a few percent of the original length. For a large number of materials, experiments show that for sufficiently small extensions the force is proportional to the extension \begin{equation} \label{Eq:II:38:1} F\propto\Delta l. \end{equation} This relation is known as Hooke’s law.

The lengthening $\Delta l$ of the bar will also depend on its length. We can figure out how by the following argument. If we cement two identical blocks together, end to end, the same forces act on each block; each will stretch by $\Delta l$. Thus, the stretch of a block of length $2l$ would be twice as big as a block of the same cross section, but of length $l$. In order to get a number more characteristic of the material, and less of any particular shape, we choose to deal with the ratio $\Delta l/l$ of the extension to the original length. This ratio is proportional to the force but independent of $l$: \begin{equation} \label{Eq:II:38:2} F\propto\frac{\Delta l}{l}. \end{equation}

The force $F$ will also depend on the area of the block. Suppose that we put two blocks side by side. Then for a given stretch $\Delta l$ we would have the force $F$ on each block, or twice as much on the combination of the two blocks. The force, for a given amount of stretch, must be proportional to the cross-sectional area $A$ of the block. To obtain a law in which the coefficient of proportionality is independent of the dimensions of the body, we write Hooke’s law for a rectangular block in the form \begin{equation} \label{Eq:II:38:3} F=YA\,\frac{\Delta l}{l}. \end{equation} The constant $Y$ is a property only of the nature of the material; it is known as Young’s modulus. (Usually you will see Young’s modulus called $E$. But we’ve used $E$ for electric fields, energy, and emf’s, so we prefer to use a different letter.)

The force per unit area is called the stress, and the stretch per unit length—the fractional stretch—is called the strain. Equation (38.3) can therefore be rewritten in the following way: \begin{gather} \label{Eq:II:38:4} \frac{F}{A}=Y\times\frac{\Delta l}{l},\\[6pt] \text{Stress}=(\text{Young’s modulus})\times(\text{Strain}).\notag \end{gather}

There is another part to Hooke’s law: When you stretch a block of material in one direction it contracts at right angles to the stretch. The contraction in width is proportional to the width $w$ and also to $\Delta l/l$. The sideways contraction is in the same proportion for both width and height, and is usually written \begin{equation} \label{Eq:II:38:5} \frac{\Delta w}{w}=\frac{\Delta h}{h}=-\sigma\,\frac{\Delta l}{l}, \end{equation} where the constant $\sigma$ is another property of the material called Poisson’s ratio. It is always positive in sign and is a number less than $1/2$. (It is “reasonable” that $\sigma$ should be generally positive, but it is not quite clear that it must be so.)

The two constants $Y$ and $\sigma$ specify completely the elastic properties of a homogeneous isotropic (that is, noncrystalline) material. In crystalline materials the stretches and contractions can be different in different directions, so there can be many more elastic constants. We will restrict our discussion temporarily to homogeneous isotropic materials whose properties can be described by $Y$ and $\sigma$. As usual there are different ways of describing things—some people like to describe the elastic properties of materials by different constants. It always takes two, and they can be related to $\sigma$ and $Y$.

The last general law we need is the principle of superposition. Since the two laws (38.4) and (38.5) are linear in the forces and in the displacements, superposition will work. If you have one set of forces and get some displacements, and then you add a new set of forces and get some additional displacements, the resulting displacements will be the sum of the ones you would get with the two sets of forces acting independently.

Now we have all the general principles—the superposition principle and Eqs. (38.4) and (38.5)—and that’s all there is to elasticity. But that is like saying that once you have Newton’s laws that’s all there is to mechanics. Or, given Maxwell’s equations, that’s all there is to electricity. It is, of course, true that with these principles you have a great deal, because with your present mathematical ability you could go a long way. We will, however, work out a few special applications.

38–2Uniform strains

As our first example let’s find out what happens to a rectangular block under uniform hydrostatic pressure. Let’s put a block under water in a pressure tank. Then there will be a force acting inward on every face of the block proportional to the area (see Fig. 38–2). Since the hydrostatic pressure is uniform, the stress (force per unit area) on each face of the block is the same. We will work out first the change in the length. The change in length of the block can be thought of as the sum of changes in length that would occur in the three independent problems which are sketched in Fig. 38–3.

Problem 1. If we push on the ends of the block with a pressure $p$, the compressional strain is $p/Y$, and it is negative, \begin{equation*} \frac{\Delta l_1}{l}=-\frac{p}{Y}. \end{equation*}

Problem 2. If we push on the two sides of the block with pressure $p$, the compressional strain is again $p/Y$, but now we want the lengthwise strain. We can get that from the sideways strain multiplied by $-\sigma$. The sideways strain is \begin{equation*} \frac{\Delta w}{w}=-\frac{p}{Y}; \end{equation*} so \begin{equation*} \frac{\Delta l_2}{l}=+\sigma\,\frac{p}{Y}. \end{equation*}

Problem 3. If we push on the top of the block, the compressional strain is once more $p/Y$, and the corresponding strain in the sideways direction is again $-\sigma p/Y$. We get \begin{equation*} \frac{\Delta l_3}{l}=+\sigma\,\frac{p}{Y}. \end{equation*}

Combining the results of the three problems—that is, taking $\Delta l=\Delta l_1+\Delta l_2+\Delta l_3$—we get \begin{equation} \label{Eq:II:38:6} \frac{\Delta l}{l}=-\frac{p}{Y}\,(1-2\sigma). \end{equation} The problem is, of course, symmetrical in all three directions; it follows that \begin{equation} \label{Eq:II:38:7} \frac{\Delta w}{w}=\frac{\Delta h}{h}=-\frac{p}{Y}\,(1-2\sigma). \end{equation}

The change in the volume under hydrostatic pressure is also of some interest. Since $V=lwh$, we can write, for small displacements, \begin{equation*} \frac{\Delta V}{V}=\frac{\Delta l}{l}+\frac{\Delta w}{w}+ \frac{\Delta h}{h}. \end{equation*} Using (38.6) and (38.7), we have \begin{equation} \label{Eq:II:38:8} \frac{\Delta V}{V}=-3\,\frac{p}{Y}\,(1-2\sigma). \end{equation} People like to call $\Delta V/V$ the volume strain and write \begin{equation*} p=-K\,\frac{\Delta V}{V}. \end{equation*} The volume stress $p$ is proportional to the volume strain—Hooke’s law once more. The coefficient $K$ is called the bulk modulus; it is related to the other constants by \begin{equation} \label{Eq:II:38:9} K=\frac{Y}{3(1-2\sigma)}. \end{equation} Since $K$ is of some practical interest, many handbooks give $Y$ and $K$ instead of $Y$ and $\sigma$. If you want $\sigma$ you can always get it from Eq. (38.9). We can also see from Eq. (38.9) that Poisson’s ratio, $\sigma$, must be less than one-half. If it were not, the bulk modulus $K$ would be negative, and the material would expand under increasing pressure. That would allow us to get mechanical energy out of any old block—it would mean that the block was in unstable equilibrium. If it started to expand it would continue by itself with a release of energy.

Now we want to consider what happens when you put a “shear” strain on something. By shear strain we mean the kind of distortion shown in Fig. 38–4. As a preliminary to this, let us look at the strains in a cube of material subjected to the forces shown in Fig. 38–5. Again we can break it up into two problems: the vertical pushes, and the horizontal pulls. Calling $A$ the area of the cube face, we have for the change in horizontal length \begin{equation} \label{Eq:II:38:10} \frac{\Delta l}{l}=\frac{1}{Y}\,\frac{F}{A}+ \sigma\,\frac{1}{Y}\,\frac{F}{A}= \frac{1+\sigma}{Y}\,\frac{F}{A}. \end{equation} The change in the vertical height is just the negative of this.

Now suppose we have the same cube and subject it to the shearing forces shown in Fig. 38–6(a). Note that all the forces have to be equal if there are to be no net torques and the cube is to be in equilibrium. (Similar forces must also exist in Fig. 38–4, since the block is in equilibrium. They are provided through the “glue” that holds the block to the table.) The cube is then said to be in a state of pure shear. But note that if we cut the cube by a plane at $45^\circ$—say along the diagonal $A$ in the figure—the total force acting across the plane is normal to the plane and is equal to $\sqrt{2}G$. The area over which this force acts is $\sqrt{2}A$; therefore, the tensile stress normal to this plane is simply $G/A$. Similarly, if we examine a plane at an angle of $45^\circ$ the other way—the diagonal $B$ in the figure—we see that there is a compressional stress normal to this plane of $-G/A$. From this, we see that the stress in a “pure shear” is equivalent to a combination of tension and compression stresses of equal strength and at right angles to each other, and at $45^\circ$ to the original faces of the cube. The internal stresses and strains are the same as we would find in the larger block of material with the forces shown in Fig. 38–6(b). But this is the problem we have already solved. The change in length of the diagonal is given by Eq. (38.10), \begin{equation} \label{Eq:II:38:11} \frac{\Delta D}{D}=\frac{1+\sigma}{Y}\,\frac{G}{A}. \end{equation} (One diagonal is shortened; the other is elongated.)

It is often convenient to express a shear strain in terms of the angle by which the cube is twisted—the angle $\theta$ in Fig. 38–7. From the geometry of the figure you can see that the horizontal shift $\delta$ of the top edge is equal to $\sqrt{2}\,\Delta D$. So \begin{equation} \label{Eq:II:38:12} \theta=\frac{\delta}{l}=\frac{\sqrt{2}\,\Delta D}{l}=2\,\frac{\Delta D}{D}. \end{equation} The shear stress $g$ is defined as the tangential force on one face divided by the area, $g=G/A$. Using Eq. (38.11) in (38.12), we get \begin{equation*} \theta=2\,\frac{1+\sigma}{Y}\,g. \end{equation*} Or, writing this in the form “stress${}={}$constant times strain,” \begin{equation} \label{Eq:II:38:13} g=\mu\theta. \end{equation} The proportionality coefficient $\mu$ is called the shear modulus (or, sometimes, the coefficient of rigidity). It is given in terms of $Y$ and $\sigma$ by \begin{equation} \label{Eq:II:38:14} \mu=\frac{Y}{2(1+\sigma)}. \end{equation} Incidentally, the shear modulus must be positive—otherwise you could get work out of a self-shearing block. From Eq. (38.14), $\sigma$ must be greater than $-1$. We know, then, that $\sigma$ must be between $-1$ and $+\tfrac{1}{2}$; in practice, however, it is always greater than zero.

As a last example of the type of situation where the stresses are uniform through the material, let’s consider the problem of a block which is stretched, while it is at the same time constrained so that no lateral contraction can take place. (Technically, it’s a little easier to compress it while keeping the sides from bulging out—but it’s the same problem.) What happens? Well, there must be sideways forces which keep it from changing its thickness—forces we don’t know off-hand but will have to calculate. It’s the same kind of problem we have already done, only with a little different algebra. We imagine forces on all three sides, as shown in Fig. 38–8; we calculate the changes in dimensions, and we choose the transverse forces to make the width and height remain constant. Following the usual arguments, we get for the three strains: \begin{align} \label{Eq:II:38:15} \frac{\Delta l_x}{l_x}&=\frac{1}{Y}\,\frac{F_x}{A_x}- \frac{\sigma}{Y}\,\frac{F_y}{A_y}- \frac{\sigma}{Y}\,\frac{F_z}{A_z}= \frac{1}{Y}\biggl[\frac{F_x}{A_x}-\sigma\biggl( \frac{F_y}{A_y}+\frac{F_z}{A_z} \biggr)\biggr],\\[3pt] \label{Eq:II:38:16} \frac{\Delta l_y}{l_y}&=\frac{1}{Y} \biggl[\frac{F_y}{A_y}-\sigma\biggl( \frac{F_x}{A_x}+\frac{F_z}{A_z} \biggr)\biggr],\\[5pt] \label{Eq:II:38:17} \frac{\Delta l_z}{l_z}&=\frac{1}{Y} \biggl[\frac{F_z}{A_z}-\sigma\biggl( \frac{F_x}{A_x}+\frac{F_y}{A_y} \biggr)\biggr]. \end{align} \begin{align} \frac{\Delta l_x}{l_x}&=\frac{1}{Y}\,\frac{F_x}{A_x}- \frac{\sigma}{Y}\,\frac{F_y}{A_y}- \frac{\sigma}{Y}\,\frac{F_z}{A_z}\notag\\[.75ex] \label{Eq:II:38:15} % ebook insert: \label{Eq:II:0:0} &=\frac{1}{Y}\biggl[\frac{F_x}{A_x}-\sigma\biggl( \frac{F_y}{A_y}+\frac{F_z}{A_z} \biggr)\biggr],\\[1ex] \label{Eq:II:38:16} \frac{\Delta l_y}{l_y}&=\frac{1}{Y} \biggl[\frac{F_y}{A_y}-\sigma\biggl( \frac{F_x}{A_x}+\frac{F_z}{A_z} \biggr)\biggr],\\[1ex] \label{Eq:II:38:17} \frac{\Delta l_z}{l_z}&=\frac{1}{Y} \biggl[\frac{F_z}{A_z}-\sigma\biggl( \frac{F_x}{A_x}+\frac{F_y}{A_y} \biggr)\biggr]. \end{align}

Now since $\Delta l_y$ and $\Delta l_z$ are supposed to be zero, Eqs. (38.16) and (38.17) give two equations relating $F_y$ and $F_z$ to $F_x$. Solving them together, we get that \begin{equation} \label{Eq:II:38:18} \frac{F_y}{A_y}=\frac{F_z}{A_z}=\frac{\sigma}{1-\sigma}\,\frac{F_x}{A_x}. \end{equation} Substituting in (38.15), we have \begin{equation} \label{Eq:II:38:19} \frac{\Delta l_x}{l_x}=\frac{1}{Y}\biggl( 1-\frac{2\sigma^2}{1-\sigma} \biggr)\frac{F_x}{A_x}=\frac{1}{Y}\biggl( \frac{1-\sigma-2\sigma^2}{1-\sigma} \biggr)\frac{F_x}{A_x}. \end{equation} \begin{align} \frac{\Delta l_x}{l_x}&=\frac{1}{Y}\biggl( 1-\frac{2\sigma^2}{1-\sigma} \biggr)\frac{F_x}{A_x}\notag\\[1ex] \label{Eq:II:38:19} &=\frac{1}{Y}\biggl( \frac{1-\sigma-2\sigma^2}{1-\sigma} \biggr)\frac{F_x}{A_x}. \end{align} Often, you will see this turned around, and with the quadratic in $\sigma$ factored out, it is then written \begin{equation} \label{Eq:II:38:20} \frac{F}{A}=\frac{1-\sigma}{(1+\sigma)(1-2\sigma)} \,Y\,\frac{\Delta l}{l}. \end{equation} When we constrain the sides, Young’s modulus gets multiplied by a complicated function of $\sigma$. As you can most easily see from Eq. (38.19), the factor in front of $Y$ is always greater than $1$. It is harder to stretch the block when the sides are held—which also means that a block is stronger when the sides are held than when they are not.

38–3The torsion bar; shear waves

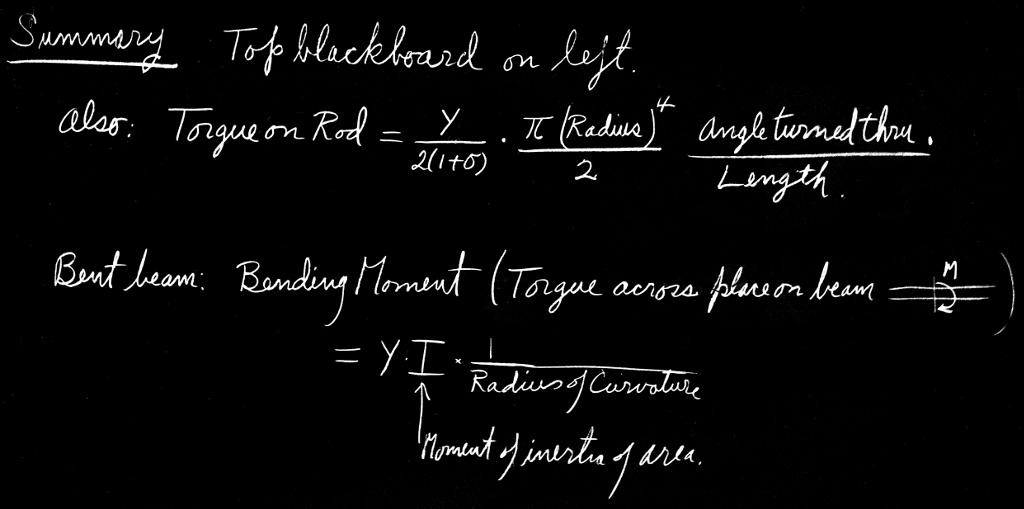

Let’s now turn our attention to an example which is more complicated because different parts of the material are stressed by different amounts. We consider a twisted rod such as you would find in a drive shaft of some machinery, or in a quartz fiber suspension used in a delicate instrument. As you probably know from experiments with the torsion pendulum, the torque on a twisted rod is proportional to the angle—the constant of proportionality obviously depending upon the length of the rod, on the radius of the rod, and on the properties of the material. The question is: In what way? We are now in a position to answer this question; it’s just a matter of working out some geometry.

Fig. 38–9(a) shows a cylindrical rod of length $L$, and radius $a$, with one end twisted by the angle $\phi$ with respect to the other. If we want to relate the strains to what we already know, we can think of the rod as being made up of many cylindrical shells and work out separately what happens to each shell. We start by looking at a thin, short cylinder of radius $r$ (less than $a$) and thickness $\Delta r$—as drawn in Fig. 38–9(b). Now if we look at a piece of this cylinder that was originally a small square, we see that it has been distorted into a parallelogram. Each such element of the cylinder is in shear, and the shear angle $\theta$ is \begin{equation*} \theta=\frac{r\phi}{L}. \end{equation*} The shear stress $g$ in the material is, therefore [from Eq. (38.13)], \begin{equation} \label{Eq:II:38:21} g=\mu\theta=\mu\,\frac{r\phi}{L}. \end{equation}

The shear stress is the tangential force $\Delta F$ on the end of the square divided by the area $\Delta l\,\Delta r$ of the end [see Fig. 38–9(c)] \begin{equation*} g=\frac{\Delta F}{\Delta l\,\Delta r}. \end{equation*} The force $\Delta F$ on the end of such a square contributes a torque $\Delta\tau$ around the axis of the rod equal to \begin{equation} \label{Eq:II:38:22} \Delta\tau=r\,\Delta F=rg\,\Delta l\,\Delta r. \end{equation} The total torque $\tau$ is the sum of such torques around a complete circumference of the cylinder. So putting together enough pieces so that the $\Delta l$’s add up to $2\pi r$, we find that the total torque, for a hollow tube, is \begin{equation} \label{Eq:II:38:23} rg(2\pi r)\,\Delta r. \end{equation} Or, using (38.21), \begin{equation} \label{Eq:II:38:24} \tau=2\pi\mu\,\frac{r^3\,\Delta r\phi}{L}. \end{equation} We get that the rotational stiffness, $\tau/\phi$, of a hollow tube is proportional to the cube of the radius $r$ and to the thickness $\Delta r$, and inversely proportional to the length $L$.

We can now imagine a solid rod to be made up of a series of concentric tubes, each twisted by the same angle $\phi$ (although the internal stresses are different for each tube). The total torque is the sum of the torques required to rotate each shell; for the solid rod \begin{equation*} \tau=2\pi\mu\,\frac{\phi}{L}\int r^3\,dr, \end{equation*} where the integral goes from $r=0$ to $r=a$, the radius of the rod. Integrating, we have \begin{equation} \label{Eq:II:38:25} \tau=\mu\,\frac{\pi a^4}{2L}\,\phi. \end{equation} For a rod in torsion, the torque is proportional to the angle and is proportional to the fourth power of the diameter—a rod twice as thick is sixteen times as stiff for torsion.

Before leaving the subject of torsion, let us apply what we have just learned to an interesting problem: torsional waves. If you take a long rod and suddenly twist one end, a wave of twist works its way along the rod, as sketched in Fig. 38–10(a). That’s a little more exciting than a steady twist—let’s see whether we can work out what happens.

Let $z$ be the distance to some point down the rod. For a static torsion the torque is the same everywhere along the rod, and is proportional to $\phi/L$, the total torsion angle over the total length. What matters to the material is the local torsional strain, which is, you will appreciate, $\ddpl{\phi}{z}$. When the torsion along the rod is not uniform, we should replace Eq. (38.25) by \begin{equation} \label{Eq:II:38:26} \tau(z)=\mu\,\frac{\pi a^4}{2}\,\ddp{\phi}{z}. \end{equation} Now let’s look at what happens to an element of length $\Delta z$ shown magnified in Fig. 38–10(b). There is a torque $\tau(z)$ at end $1$ of the little hunk of rod, and a different torque $\tau(z+\Delta z)$ at end $2$. If $\Delta z$ is small enough, we can use a Taylor expansion and write \begin{equation} \label{Eq:II:38:27} \tau(z+\Delta z)=\tau(z)+\biggl(\ddp{\tau}{z}\biggr)\Delta z. \end{equation}

The net torque $\Delta\tau$ acting on the little piece of rod between $z$ and $z+\Delta z$ is clearly the difference between $\tau(z)$ and $\tau(z+\Delta z)$, or $\Delta\tau=(\ddpl{\tau}{z})\,\Delta z$. Differentiating Eq. (38.26), we get \begin{equation} \label{Eq:II:38:28} \Delta\tau=\mu\,\frac{\pi a^4}{2}\, \frac{\partial^2\phi}{\partial z^2}\,\Delta z. \end{equation}

The effect of this net torque is to give an angular acceleration to the little slice of the rod. The mass of the slice is \begin{equation*} \Delta M=(\pi a^2\,\Delta z)\rho, \end{equation*} where $\rho$ is the density of the material. We worked out in Chapter 19, Vol. I, that the moment of inertia of a circular cylinder is $mr^2/2$; calling the moment of inertia of our piece $\Delta I$, we have \begin{equation} \label{Eq:II:38:29} \Delta I=\frac{\pi}{2}\,\rho a^4\,\Delta z. \end{equation} Newton’s law says the torque is equal to the moment of inertia times the angular acceleration, or \begin{equation} \label{Eq:II:38:30} \Delta\tau=\Delta I\,\frac{\partial^2\phi}{\partial t^2}. \end{equation} Pulling everything together, we get \begin{equation} \mu\,\frac{\pi a^4}{2}\, \frac{\partial^2\phi}{\partial z^2}\,\Delta z= \frac{\pi}{2}\,\rho a^4\,\Delta z\, \frac{\partial^2\phi}{\partial t^2},\notag \end{equation} or \begin{equation} \label{Eq:II:38:31} \frac{\partial^2\phi}{\partial z^2}-\frac{\rho}{\mu}\, \frac{\partial^2\phi}{\partial t^2}=0. \end{equation} You will recognize this as the one-dimensional wave equation. We have found that waves of torsion will propagate down the rod with the speed \begin{equation} \label{Eq:II:38:32} C_{\text{shear}}=\sqrt{\frac{\mu}{\rho}}. \end{equation} The denser the rod—for the same stiffness—the slower the waves; and the stiffer the rod, the quicker the waves work their way down. The speed does not depend upon the diameter of the rod.

Torsional waves are a special example of shear waves. In general, shear waves are those in which the strains do not change the volume of any part of the material. In torsional waves, we have a particular distribution of such shear stresses—namely, distributed on a circle. But for any arrangement of shear stresses, waves will propagate with the same speed—the one given in Eq. (38.32). For example, the seismologists find such shear waves travelling in the interior of the earth.

We can have another kind of a wave in the elastic world inside a solid material. If you push something, you can start “longitudinal” waves—also called “compressional” waves. They are like the sound waves in air or in water—the displacements are in the same direction as the wave propagation. (At the surfaces of an elastic body there can also be other types of waves—called “Rayleigh waves” or “Love waves.” In them, the strains are neither purely longitudinal nor purely transverse. We will not have time to study them.)

While we’re on the subject of waves, what is the velocity of the pure compressional waves in a large solid body like the earth? We say “large” because the speed of sound in a thick body is different from what it is, for instance, along a thin rod. By a “thick” body we mean one in which the transverse dimensions are much larger than the wavelength of the sound. Then, when we push on the object, it cannot expand sideways—it can only compress in one dimension. Fortunately, we have already worked out the special case of the compression of a constrained elastic material. We have also worked out in Chapter 47, Vol. I, the speed of sound waves in a gas. Following the same arguments you can see that the speed of sound in a solid is equal to $\sqrt{Y'/\rho}$, where $Y'$ is the “longitudinal modulus”—or pressure divided by the relative change in length—for the constrained case. This is just the ratio of $\Delta l/l$ to $F/A$ we got in Eq. (38.20). So the speed of the longitudinal waves is given by \begin{equation} \label{Eq:II:38:33} C_{\text{long}}^2=\frac{Y'}{\rho}= \frac{1-\sigma}{(1+\sigma)(1-2\sigma)}\,\frac{Y}{\rho}. \end{equation}

So long as $\sigma$ is between zero and $1/2$, the shear modulus $\mu$ is less than Young’s modulus $Y$, and also $Y'$ is greater than $Y$, so \begin{equation*} \mu<Y<Y'. \end{equation*} This means that longitudinal waves travel faster than shear waves. One of the most precise ways of measuring the elastic constants of a substance is by measuring the density of the material and the speeds of the two kinds of waves. From this information one can get both $Y$ and $\sigma$. It is, incidentally, by measuring the difference in the arrival times of the two kinds of waves from an earthquake that a seismologist can estimate—even from the signals at only one station—the distance to the quake.

38–4The bent beam

We want now to look at another practical matter—the bending of a rod or a beam. What are the forces when we bend a bar of some arbitrary cross section? We will work it out thinking of a bar with a circular cross section, but our answer will be good for any shape. To save time, however, we will cut some corners, so our theory we will work out is only approximate. Our results will be correct only when the radius of the bend is much larger than the thickness of the beam.

Suppose you grab the two ends of a straight bar and bend it into some curve like the one shown in Fig. 38–11. What goes on inside the bar? Well, if it is curved, that means that the material on the inside of the curve is compressed and the material on the outside is stretched. There is some surface which goes along more or less parallel to the axis of the bar that is neither stretched nor compressed. This is called the neutral surface. You would expect this surface to be near the “middle” of the cross section. It can be shown (but we won’t do it here) that, for small bending of simple beams, the neutral surface goes through the “center of gravity” of the cross section. This is true only for “pure” bending—if you are not stretching or compressing the beam at the same time.

For pure bending, then, a thin transverse slice of the bar is distorted as shown in Fig. 38–12(a). The material below the neutral surface has a compressional strain which is proportional to the distance from the neutral surface; and the material above is stretched, also in proportion to its distance from the neutral surface. So the longitudinal stretch $\Delta l$ is proportional to the height $y$. The constant of proportionality is just $l$ over the radius of curvature of the bar—see Fig. 38–12: \begin{equation*} \frac{\Delta l}{l}=\frac{y}{R}. \end{equation*} So the force per unit area—the stress—in a small strip at $y$ is also proportional to the distance from the neutral surface \begin{equation} \label{Eq:II:38:34} \frac{\Delta F}{\Delta A}=Y\,\frac{y}{R}. \end{equation}

Now let’s look at the forces that would produce such a strain. The forces acting on the little segment drawn in Fig. 38–12 are shown in the figure. If we think of any transverse cut, the forces acting across it are one way above the neutral surface and the other way below. They come in pairs to make a “bending moment” $\bendingMom$—by which we mean the torque about the neutral line. We can compute the total moment by integrating the force times the distance from the neutral surface for one of the faces of the segment of Fig. 38–12: \begin{equation} \label{Eq:II:38:35} \bendingMom=\underset{\substack{\text{cross}\\\text{sect}}}{\int} y\,dF. \end{equation} From Eq. (38.34), $dF=Yy/R\,dA$, so \begin{equation*} \bendingMom=\frac{Y}{R}\int y^2\,dA. \end{equation*} The integral of $y^2\,dA$ is what we can call the “moment of inertia” of the geometric cross section about a horizontal axis through its “center of mass”;1 we will call it $I$: \begin{align} \label{Eq:II:38:36} \bendingMom&=\frac{YI}{R}\\[2ex] \label{Eq:II:38:37} I&=\int y^2\,dA. \end{align}

Equation (38.36), then, gives us the relation between the bending moment $\bendingMom$ and the curvature $1/R$ of the beam. The “stiffness” of the beam is proportional to $Y$ and to the moment of inertia $I$. In other words, if you want the stiffest possible beam with a given amount of, say, aluminum, you want to put as much of it as possible as far as you can from the neutral surface, to make a large moment of inertia. You can’t carry this to an extreme, however, because then the thing will not curve as we have supposed—it will buckle or twist and become weaker again. But now you see why structural beams are made in the form of an I or an H—as shown in Fig. 38–13.

As an example of the use of our beam equation (38.36), let’s work out the deflection of a cantilevered beam with a concentrated force $W$ acting at the free end, as sketched in Fig. 38–14. (By “cantilevered” we simply mean that the beam is supported in such a way that both the position and the slope are fixed at one end—it is stuck into a cement wall.) What is the shape of the beam? Let’s call the deflection at the distance $x$ from the fixed end $z$; we want to know $z(x)$. We’ll work it out only for small deflections. We will also assume that the beam is long in comparison with its cross section. Now, as you know from your mathematics courses, the curvature $1/R$ of any curve $z(x)$ is given by \begin{equation} \label{Eq:II:38:38} \frac{1}{R}=\frac{d^2z/dx^2}{[1+(dz/dx)^2]^{3/2}}. \end{equation} Since we are interested only in small slopes—this is usually the case in engineering structures—we neglect $(dz/dx)^2$ in comparison with $1$, and take \begin{equation} \label{Eq:II:38:39} \frac{1}{R}=\frac{d^2z}{dx^2}. \end{equation} We also need to know the bending moment $\bendingMom$. It is a function of $x$ because it is equal to the torque about the neutral axis of any cross section. Let’s neglect the weight of the beam and take only the downward force $W$ at the end of the beam. (You can put in the beam weight yourself if you want.) Then the bending moment at $x$ is \begin{equation*} \bendingMom(x)=W(L-x), \end{equation*} because that is the torque about the point at $x$, exerted by the weight $W$—the torque which the beam must support at $x$. We get \begin{equation} W(L-x)=\frac{YI}{R}=YI\,\frac{d^2z}{dx^2}\notag \end{equation} or \begin{equation} \label{Eq:II:38:40} \frac{d^2z}{dx^2}=\frac{W}{YI}\,(L-x). \end{equation} This one we can integrate without any tricks; we get \begin{equation} \label{Eq:II:38:41} z=\frac{W}{YI}\biggl( \frac{Lx^2}{2}-\frac{x^3}{6} \biggr), \end{equation} using our assumptions that $z(0)=0$ and that $dz/dx$ is also zero at $x=0$. That is the shape of the beam. The displacement of the end is \begin{equation} \label{Eq:II:38:42} z(L)=\frac{W}{YI}\,\frac{L^3}{3}; \end{equation} the displacement of the end of a beam increases as the cube of the length.

In deriving our approximate beam theory, we have assumed that the cross section of the beam did not change when the beam was bent. When the thickness of the beam is small compared to the radius of curvature, the cross section changes very little and our result is O.K. In general, however, this effect cannot be neglected, as you can easily demonstrate for yourselves by bending a soft-rubber eraser in your fingers. If the cross section was originally rectangular, you will find that when it is bent it bulges at the bottom (see Fig. 38–15). This happens because when we compress the bottom, the material expands sideways—as described by Poisson’s ratio. Rubber is easy to bend or stretch, but it is somewhat like a liquid in that it’s hard to change the volume—as shows up nicely when you bend the eraser. For an incompressible material, Poisson’s ratio would be exactly $1/2$—for rubber it is nearly that.

38–5Buckling

We want now to use our beam theory to understand the theory of the “buckling” of beams, or columns, or rods. Consider the situation sketched in Fig. 38–16 in which a rod that would normally be straight is held in its bent shape by two opposite forces that push on the ends of the rod. We would like to calculate the shape of the rod and the magnitude of the forces on the ends.

Let the deflection of the rod from the straight line between the ends be $y(x)$, where $x$ is the distance from one end. The bending moment $\bendingMom$ at the point $P$ in the figure is equal to the force $F$ multiplied by the moment arm, which is the perpendicular distance $y$, \begin{equation} \label{Eq:II:38:43} \bendingMom(x)=Fy. \end{equation} Using the beam equation (38.36), we have \begin{equation} \label{Eq:II:38:44} \frac{YI}{R}=Fy. \end{equation} For small deflections, we can take $1/R=-d^2y/dx^2$ (the minus sign because the curvature is downward). We get \begin{equation} \label{Eq:II:38:45} \frac{d^2y}{dx^2}=-\frac{F}{YI}\,y, \end{equation} which is the differential equation of a sine wave. So for small deflections, the curve of such a bent beam is a sine curve. The “wavelength” $\lambda$ of the sine wave is twice the distance $L$ between the ends. If the bending is small, this is just twice the unbent length of the rod. So the curve is \begin{equation*} y=K\sin\pi x/L. \end{equation*} Taking the second derivative, we get \begin{equation*} \frac{d^2y}{dx^2}=-\frac{\pi^2}{L^2}\,y. \end{equation*} Comparing this to Eq. (38.45), we see that the force is \begin{equation} \label{Eq:II:38:46} F=\pi^2\,\frac{YI}{L^2}. \end{equation} For small bendings the force is independent of the bending displacement $y$!

We have, then, the following thing physically. If the force is less than the $F$ given in Eq. (38.46), there will be no bending at all. But if it is slightly greater than this force, the material will suddenly bend a large amount—that is, for forces above the critical force $\pi^2YI/L^2$ (often called the “Euler force”) the beam will “buckle.” If the loading on the second floor of a building exceeds the Euler force for the supporting columns, the building will collapse. Another place where the buckling force is most important is in space rockets. On one hand, the rocket must be able to hold its own weight on the launching pad and endure the stresses during acceleration; on the other hand, it is important to keep the weight of the structure to a minimum, so that the payload and fuel capacity may be made as large as possible.

Actually a beam will not necessarily collapse completely when the force exceeds the Euler force. When the displacements get large, the force is larger than what we have found because of the terms in $1/R$ in Eq. (38.38) that we have neglected. To find the forces for a large bending of the beam, we have to go back to the exact equation, Eq. (38.44), which we had before we used the approximate relation between $R$ and $y$. Equation (38.44) has a rather simple geometrical property.2 It’s a little complicated to work out, but rather interesting. Instead of describing the curve in terms of $x$ and $y$, we can use two new variables: $S$, the distance along the curve, and $\theta$ the slope of the tangent to the curve. See Fig. 38–17. The curvature is the rate of change of angle with distance: \begin{equation*} \frac{1}{R}=\ddt{\theta}{S}. \end{equation*} We can, therefore write the exact equation (38.44) as \begin{equation*} \ddt{\theta}{S}=-\frac{F}{YI}\,y. \end{equation*} If we take the derivative of this equation with respect to $S$ and replace $dy/dS$ by $\sin\theta$, we get \begin{equation} \label{Eq:II:38:47} \frac{d^2\theta}{dS^2}=-\frac{F}{YI}\sin\theta. \end{equation} [If $\theta$ is small, we get back Eq. (38.45). Everything is O.K.]

Now it may or may not delight you to know that Eq. (38.47) is exactly the same one you get for the large amplitude oscillations of a pendulum—with $F/YI$ replaced by another constant, of course. We learned way back in Chapter 9, Vol. I, how to find the solution of such an equation by a numerical calculation.3 The answers you get are some fascinating curves—known as the curves of the “Elastica.” Figure 38–18 shows three curves for different values of $F/YI$.

- It is, of course, really the moment of inertia of a slice with unit mass per unit area. ↩

- The same equation appears, incidentally, in other physical situations—for example, the meniscus at the surface of a liquid contained between parallel planes—and the same geometrical solution can be used. ↩

- The solutions can also be expressed in terms of some functions, called the “Jacobian elliptic functions,” that someone else has already computed. ↩